Technology

ADVANCED TECHNICAL EXPERIENCE

Closed

MAXIMIZE RESULTS

Direct technical support is always available to provide expert guidance in the following areas:

- Regional Intelligence fracturing searches

- Analysis of DFIT and Step Rate Tests

- Additive optimization

- Laboratory testing

- Geoscience support

- Reservoir characterization

- Petrophysical and geomechanical log processing

- Hydraulic fracture modeling

- Treatment design selection

- Lateral placement optimization

- Advanced 3D simulations

- Pad design – multiple horizontal wells

- Parent-child interactions

- Stress shadowing

- Cluster design

- Post-frac analytics

- Real-time fracture monitoring

ADVANCED TECHNICAL EXPERIENCE

Calfrac’s Asset Enhancement services team provides advanced technical expertise and in-depth analyses for your reservoir. Our multidisciplinary approach incorporates best practices from reservoir characterization, hydraulic fracturing design and placement operations to improve efficiencies and provide the necessary information and advice to make more informed business decisions.

RESERVOIR CHARACTERIZATION

Every reservoir and every well is unique. Expert evaluation of reservoir characteristics allows the stimulation program to be tailored to your reservoir. This customization results in the most effective treatment for your pressure pumping program.

POST-FRAC PERFORMANCE ANALYSIS

Our partnership does not end after hydraulic fracturing. We provide the follow-up analysis required to assess a treatment’s effectiveness and help to refine and optimize future stimulations.

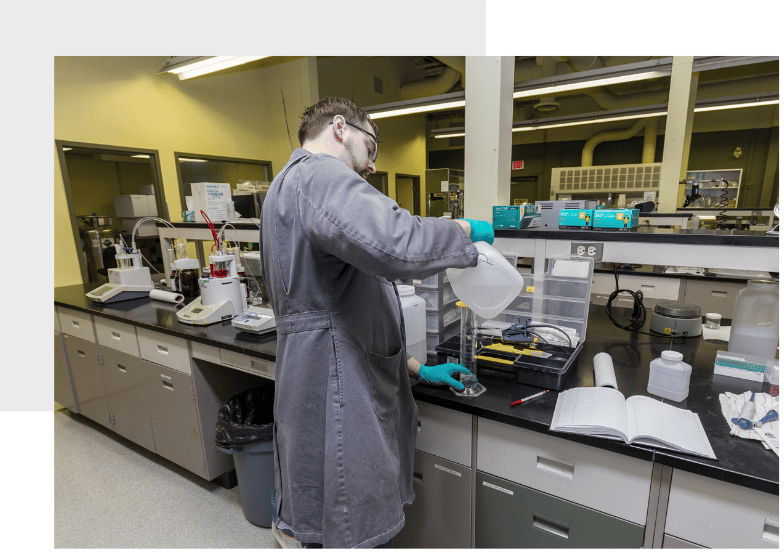

STATE-OF-THE-ART LABORATORIES

Our labs are positioned in strategic Calfrac district locations with regional labs servicing the United States and Canada to ensure that direct support is always available to our customers and operations.

- Product development and custom product blend formulation

- Complete fracture fluid optimization evaluations

- Friction reducer selection and optimization via flow-loop testing

- API STD 19C / ISO 13503 proppant analysis

- Advanced Rheological Fluid Studies including ultra low shear rate measurements and visco-elastic properties

- Routine and extended metals water analysis

- Fluid Compatibility Testing

- Emulsion testing and analysis

- Packed column testing for surfactant evaluation

- Microbial and biocide kill studies

- Scaling tendency modeling and dynamic tube block studies

- High-Temperature Corrosion Testing

- Fracture Fluids Proppant Pack Damage Evaluations

Mobile and On-Site Lab Capabilities:

- Well site quality control and intervention.

- Real-time / in-line viscosity, pH and conductivity measurement

- Proppant analysis

- Rheology and gel stability testing

- Viscosity testing and reporting

TECHNICAL TRAINING & EDUCATION

Our customers’ success increases when they understand what we do, so we’re always available to ensure your employees are up-to-date on the latest fracturing technologies and trends. We provide with technical training workshops and presentations customized around what you would like to learn.

EQUIPMENT INNOVATION

Calfrac’s investment in equipment innovation includes proprietary designs and strategic alliances with key manufacturers. Equipment technologies and maintenance programs are in place to ensure we meet or exceed regulatory requirements to reduce emissions and noise.